Publications

Hettel, M., Daymo, E., Sawant, N., Deutschmann, O. 2D Lattice Boltzmann with detailed surface chemistry: Conservation of geometrical surface. Chemical Engineering Science, 2026. https://doi.org/10.1016/j.ces.2025.122797

Daymo, E., Hettel, M. Fixed bed reactor modeling with internal and external transport resistances: Comparing 3D PRCFD and 2D porous media simulations. Chemical Engineering Science, 2026. https://doi.org/10.1016/j.ces.2025.122779

Hettel, M., Bukreev, F., Daymo, E., Kummerländer, A., Krause, M., Deutschmann, O.

Calculation of Single and Multiple Low Reynolds Number Free Jets with a Lattice-Boltzmann Method. AIAAJ, 2025. https://doi.org/10.2514/1.J064280

Daymo, E.A., Tonkovich, A.L., Hettel, M., Shirsath, A. 1D and 2D porous media fixed bed reactor simulations with DUO. Meccanica, 2024. https://doi.org/10.1007/s11012-024-01764-8

Hettel, M., Burkeev, F., Daymo, E., Kummerländer, A., Krause, M., Deutschmann, O. Calculation of Single and Multiple Low Reynolds Number Free Jets with a Lattice-Boltzmann Method. AIAA J, 2024. https://doi.org/10.2514/1.J064280

Daymo, E.A., Tonkovich, A.L., Hettel, M., Shirsath, A. 1D and 2D porous media fixed bed reactor simulations with DUO: Steam Methane Reforming (SMR) validation test. IOP Conf. Ser.: Mater. Sci. Eng., 2024. https://doi.org/10.1088/1757-899X/1312/1/012004

Tonkovich, A., Daymo, E., Shirsath, A., Hettel, M., Deutschmann, O., Lockhart, C., Seabaugh, M. Uncover the secret life of catalysts with accessible reaction engineering tools: DRM and RWGS. Proceedings of the AIChE Spring 2024 Meeting. https://www.omegadot.software/secret-life-catalysts.pdf

Zhang, R., Li, J., Tonkovich, A., Lockhart, C., Wang, X., Hu, W., Karroum, H., Seabaugh, M., Kruse, N., Wang, Y. Highly productive and robust core@shell HeatPath SiC-Al2O3 @Co/Re/Al2O3 catalyst for Fischer–Tropsch synthesis. App. Cat A, 2023. https://heatpathsolutions.com/wp-content/uploads/2024/01/HeatPath-FT-Paper-2023.pdf

Gossler, H., Riedel, J., Daymo E., Chacko R., Angeli S., Deutschmann, O. A New Approach to Research Data Management with a Focus on Traceability: Adacta, Chemie Ingenieur Technik, 2022. https://doi.org/10.1002/cite.202200064

Daymo, E., Hettel, M., Deutschmann, O., Wehinger, G. Accelerating particle-resolved CFD simulations of catalytic fixed-bed reactors with DUO, Chemical Engineering Science, 2022. https://doi.org/10.1016/j.ces.2021.117408

O. Deutschmann, S. Tischer, C. Correa, D. Chatterjee, S. Kleditzsch, V.M. Janardhanan, N. Mladenov, H. D. Minh, H. Karadeniz, M. Hettel, V. Menon, A. Banerjee, H. Goßler, E. Daymo, DETCHEM Software package, 2.8 ed., www.detchem.com, Karlsruhe 2020.

Hettel, M., Daymo, E., Schmidt, T., Deutschmann, O. CFD-Modeling of Fluid Domains with Embedded Monoliths with Emphasis on Automotive Converters, Chemical Engineering and Processing - Process Intensification, 2019. https://doi.org/10.1016/j.cep.2019.107728

Daymo, E., Tonkovich, A., Hettel, M., Guerrero, J. Accelerating Reactor Development with Accessible Simulation and Automated Optimization Tools, Chemical Engineering and Processing - Process Intensification, 2019. https://doi.org/10.1016/j.cep.2019.107582

Benzinger, W., Daymo, E., Hettel, M., Maier, L., Antinori, C., Pfeifer, P., Deustchmann, O. Reverse Water Gas Shift (RWGS) over Ni – Spatially-Resolved Measurements and Simulations, Chemical Engineering Journal, 2019. https://doi.org/10.1016/j.cej.2019.01.038

Tonkovich, A., and E. Daymo "Process Intensification", Handbook of Thermal Science and Engineering, Ed. F.A. Kulacki. Springer, 2017. https://doi.org/10.1007/978-3-319-32003-8_34-1

Hettel, M., Daymo, E., Deustchmann, O. 3D Modeling of a CPOX-Reformer including Detailed Chemistry and Radiation Effects with DUO, Computers and Chemical Engineering, 2017. https://doi.org/10.1016/j.compchemeng.2017.11.005

Case Study Index

Scale-up of Algal Ponds (Dynamic flow study to design turning vanes that avoid flow stagnation)

Chemical Kinetics and Reactor Design (Methane Catalytic Partial oxidation)

Droplet Formation (Emulsion formation)

Multicomponent Diffusion with Chemical Reaction (Reverse Water Gas Shift)

Bioreactor mixing and VVM (Bio-reactor mixing as a function of air flow per vessel volume)

Machine learning applied to CFD for design optimization (Example of higher yield and lower peak temperature for a partial oxidation reaction to produce hydrogen)

Turbulent flow using Large Eddy Simulation (LES) Downstream of Monolith Reactors

Case Study - 1

Scale-up of Algal Ponds

Algal ponds often show reduced performance at increased production scales. Small reactors are easy to mix and produce minimal dead zones. As the volume increases, considerable recirculation zones can form and mixing deteriorates. Design optimization with the use of Computational Fluid Dynamics (CFD) can specify the number and location of turning vanes along with paddlewheel placement.

Strain selection, growth cycles, and nutrient optimization happen in flasks before validation in small ponds. Results must meet economic model targets before moving to scale-up. The surface of a pond can be observed and validated with the use of CFD. The flow beneath the surface cannot be seen and is analyzed with CFD to identify recirculation zones and optimize design details. Success occurs when the final product is growing well, reproducibly and meeting economic targets.

The surface of a pond can be observed and modeled using Computational Fluid Dynamics (CFD).

The transient flow pattern beneath the surface can not be seen but can be analyzed using CFD. The impact of turning vanes on flow recirculation and be assessed to optimize reactor design and performance.

Case Study - 2

Chemical Kinetics and Reactor Design

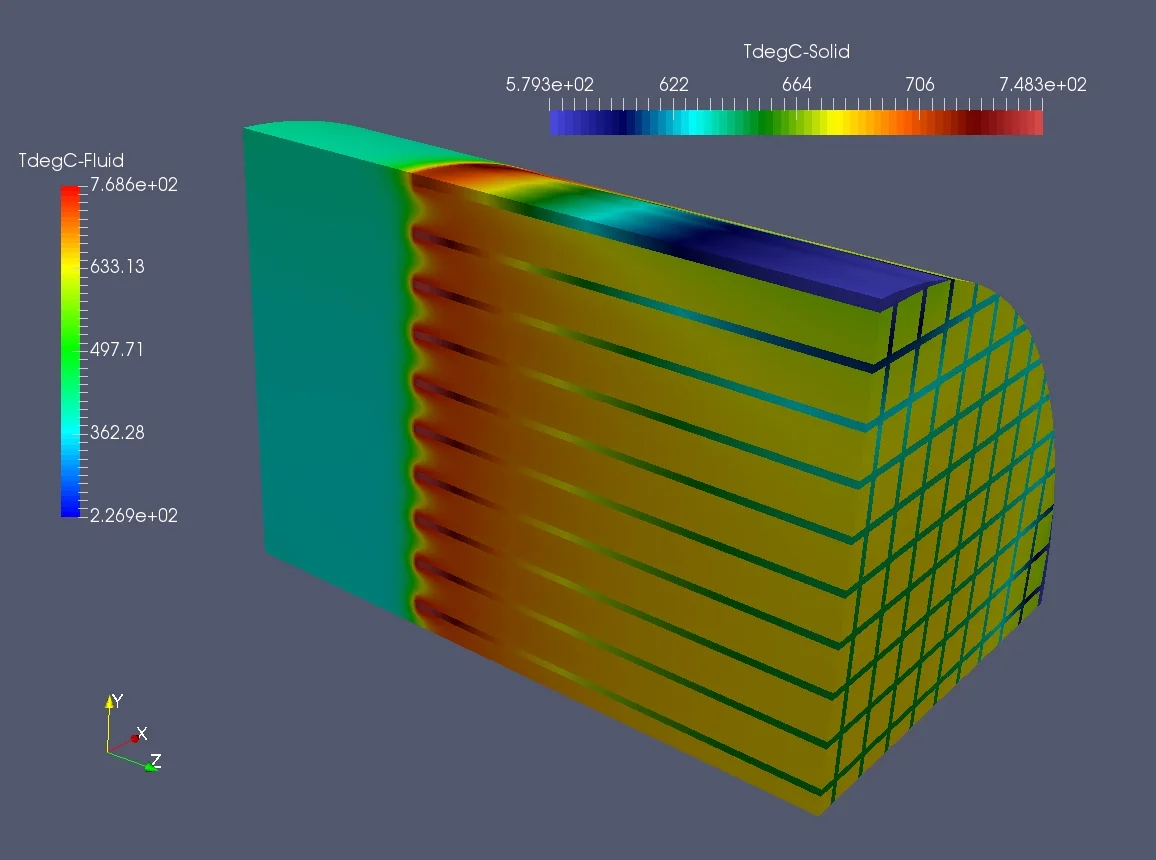

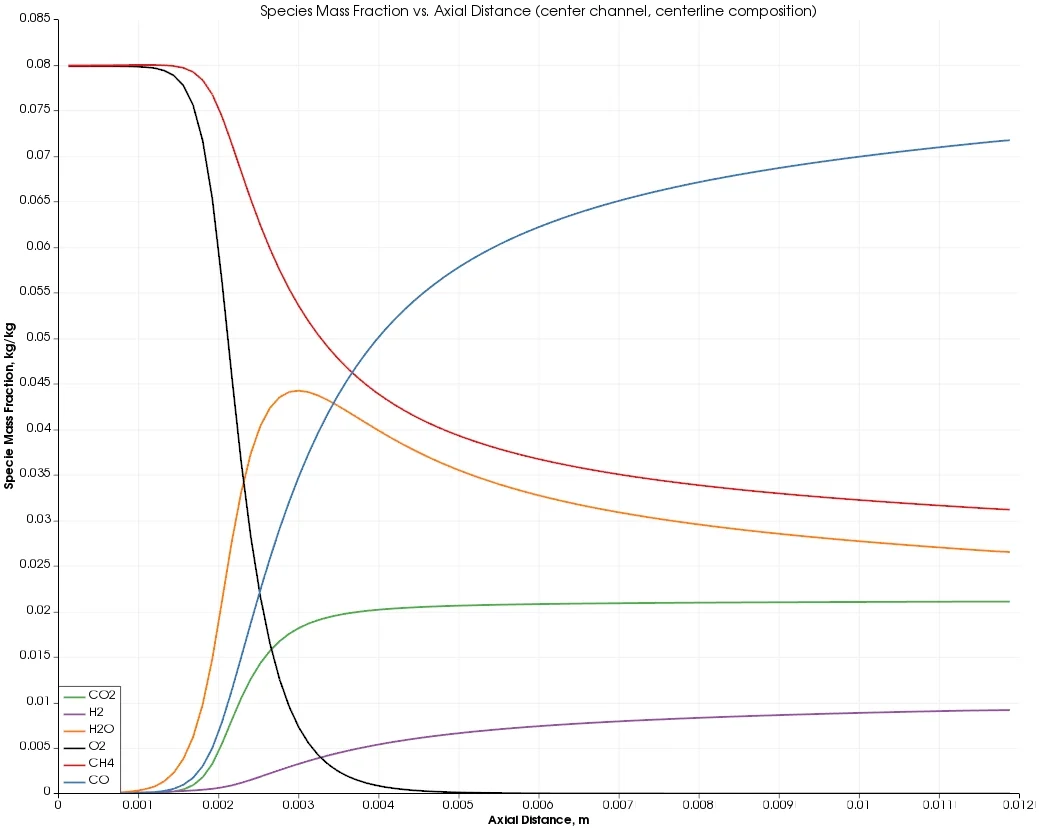

Designing and debugging problems with catalytic reactors is aided with the use of reactive Computational Fluid Dynamics (CFD). The methane catalytic partial oxidation reaction was studied with the heterogeneous CFD code, DETCHEM DUO. A complete catalytic mechanism on a Rhodium catalyst is available for this reaction. A conjugate heat transfer analysis with a catalytic elementary-step reaction mechanism quantified composition and temperature within a single channel and a multichannel monolith (figures shown below). Heat losses in the laboratory-scale multichannel monolith were quantified to allow predictive scale-up design. Reactor model predictions matched experimental data.

Often industrial catalytic reactions do not have available detailed chemical reaction mechanisms and kinetics. Further, solving reactor problems is often time sensitive and impractical to quickly develop a detailed set of elementary steps.

The reactive CFD code can be used to fit apparent kinetics from available experimental data as a precursor to understanding the root cause of reactor problems and then vet potential solutions. Apparent kinetics may be a few to about ten steps rather than hundreds of steps found in a typical elementary-step mechanism. Further, apparent rate forms may be power law, “1+”, or others as deduced from the experimental data. Data analysis includes the fitting of activation energies, pre-exponentials, reaction orders, and adsorption terms as necessary.

Practical recommendations are made for the industrial user to resolve the reactor problem. Typical recommendations may include changes in design, laboratory set up or operation, or to the catalyst itself.

Some catalytic oxidation reactions are further challenged by competing (and often unwanted) homogeneous reactions. Homogeneous gas phase kinetic mechanisms and parameters are readily available and are used in conjunction with heterogeneous kinetics. Conjugate heat transfer and reaction models assess performance loss from competitive homogeneous reactions, understand safety considerations, and design complete systems that may require reactant safe mixing in a potentially flammable region.

Liquid phase reactions may occur in the bulk or at a catalytic interface. Mixing and mass transfer is often an important consideration for liquid phase reactions due to slow diffusion and low velocity. Reactive CFD analysis can identify design issues and develop alternatives to improve conversion, reduce side products, and lower costs with compact hardware.

A quarter-symmetry monolith for the catalytic partial oxidation of methane with exterior heat losses in a laboratory-scale reactor.

Composition along the length of a catalytic methane partial oxidation reactor using a detailed kinetic mechanism and reactive CFD.

Case Study - 3

Droplet Formation can be predicted with knowledge of fluid properties (density, surface tension, contact angle), dimensions (height, width, length), and flowrate of each phase. Design custom microfluidic hardware. Improved visualization (droplet detachment shown on left using Blender and with standard CFD visualization tools on the right) helps to understand results and communicate with stakeholders.

Case Study - 4

Multicomponent Diffusion with Chemical Reaction

Under some conditions (low flows of highly mobile molecules, like hydrogen), accurate diffusion modeling improves reactive system design. OpenFOAM’s standard solvers assume all gas molecules have the same diffusion coefficient (i.e., Schmidt Number = 1). More realistic diffusion models improve accuracy under reactive laminar flow.

In collaboration with the Karlsruhe Institute of Technology (KIT), several diffusion approaches were implemented in DETCHEM DUO to capture concentration profiles in reactive laminar flow. In order of increasing complexity and accuracy, DUO can perform the species balance assuming Fickian mixture-averaged diffusion, the Hirschfelder-Curtiss approximation for mixture-averaged diffusion, and full multicomponent diffusion (solving the Maxwell-Stefan equations).

Concentration profiles were evaluated in a single channel of a Reverse Water Gas Shift (RWGS) monolithic reactor. At low flow (< 0.1 m/s) inlet conditions, which emphasize forward-diffusion of the reactants and back-diffusion of the products for the rich hydrogen feed composition, equivalent concentration profiles are predicted by both DUO and FLUENT.

Correct model assumptions are vital for engineering cost-effective solutions. OpenFOAM coupled with DUO for reacting flow is an excellent CFD platform with vastly lower licensing costs. It is extendable and transparent, to remove guesses about model parameters or methods for reactor design and scale-up.

Concentration profiles for the Reverse Water Gas Shift (RWGS) reaction comparing DETCHEM DUO with FLUENT results

Case Study - 5

Bioreactor Mixing and VVM

The amount of air added to a bubble column, fermenter, or bio-reactor are important variables for mixing as well as oxygen transfer. Both VVM (volume of air per minute per vessel volume) and sparger design play a role to achieve good mixing and minimize dead zones. A ring sparger placed near the perimeter and bottom of a large vessel (100,000-L) was analyzed using CFD. A snapshot of the air volume fraction for a VVM of 0.14 (left) and VVM of 0.5 (right) is shown below. At low VVM (0.14), air by-passes most of the water with little tank mixing for a poorly mixed system. At higher VVM (0.5), both phases mix well in a chaotic manner except near the vessel bottom due to the particular sparger design. Improved sparger designs and high VVM support a well mixed bio-reactor with minimal dead zones. When needed, impeller mixing can be added when high OTR (Oxygen Transfer Rate) is required for high activity biological reactors.

Case Study - 6

CFD automated optimization with machine learning

Optimized solutions for chemical reactors were developed by coupling CFD with automated optimization tools using the principles of machine learning. Open-source CFD (OpenFOAM) coupled with chemical reactor (DETCHEM) and optimization (DAKOTA) tools found unique design spaces. The published example focused on methane partial oxidation, where the peak temperature was reduced by 120 C, while concurrently increasing hydrogen yield per volume by 1.6x.

Automated CFD optimization builds on machine learning. Apply to any system described with numerical techniques such as CFD to optimize any or many metrics (cost, weight, productivity, yield, design life, pressure drop).

Machine learning applied to chemical reactors to optimize and find non-obvious solutions

Case Study - 7

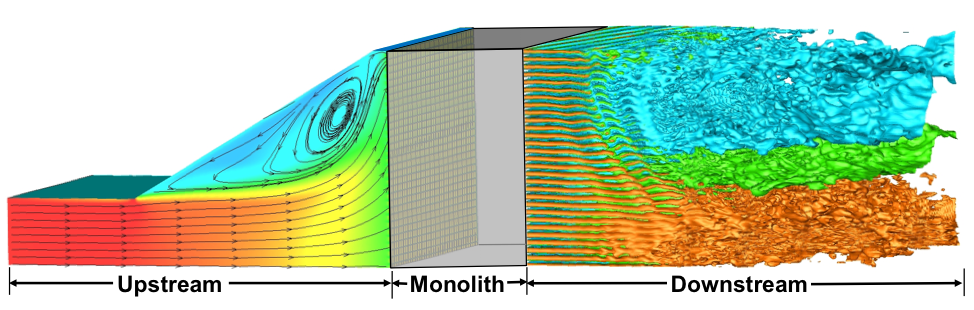

In monolith reactor systems (like an automotive catalytic converter) laminar flow inside millimeter scale channels is bounded by upstream and downstream turbulent flow.

In some applications, like determining the optimal placement of an automotive lambda probe (oxygen sensor), accurate downstream modeling is important. Capturing the transient transition regime between laminar to turbulent flow, is only possible with computationally intensive Large Eddy Simulation (LES) turbulence models. The upstream section was simulated using a k-Omega SST RANS turbulent model which averages transient eddies.

Tonkomo collaborated with the Karlsurhe Institute of Technology to develop computationally efficient methods to analyze the upstream and downstream regions of a monolith reactor. This time-saving approach allows engineers to focus precious computational resources on the critical problem, such as the turbulent flow field downstream of the monolith.

The new method is substantially faster than conventional CFD, while still allowing exploration of subtle features like the transition from laminar to turbulent flow downstream of the monolith. The movie clearly shows the transition from laminar to turbulence at about a half-monolith diameter downstream. The movie covers about 0.02 seconds, capturing the outlet velocity (in m/s) from 30 outlets near the center of the monolith. The full simulation domain was 39 mm high x 48 mm wide x 60 mm long.

“The most difficult thing is the decision to act, the rest is merely tenacity.”